Domino launches variable data printing solution for pharmaceutical applications

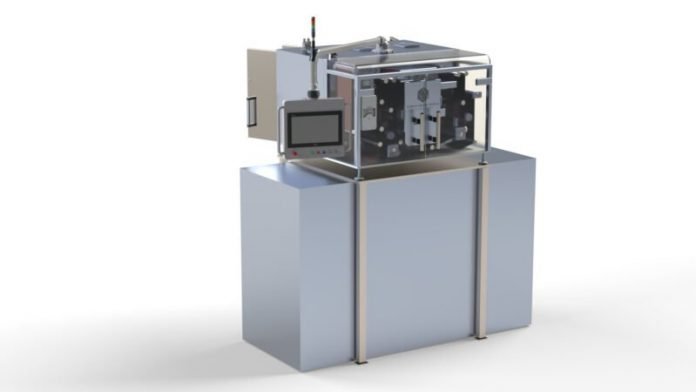

Domino Printing Sciences (Domino) recently announced the launch of the new K6 00G – a new blister foil and web digital printing solution for production-level serialization in pharmaceutical applications.

Developed in collaboration with pharmaceutical industry innovator Gallarus, and with engagement from life science industry experts SeaVision, the K6 00G is a ground-breaking, loftier-resolution, digital printing solution. The result of successful teamwork between marketplace leaders in digital print and life scientific discipline experts, the K6 00G promises to meet the needs of pharmaceutical manufacturers now and in the future.

" Over the terminal couple of years, serialization at pack level has become a global requirement in the pharmaceutical manufacture," says Craig Stobie, director of Global Sector Evolution at Domino. "In the future, it is likely that serialization of private pockets of a cicatrice pack will become the new standard, to further enhance patient safety and reduce medical errors.

" The K6 00G has been adult to provide manufacturers with an on-site solution for variable data press, which includes coding at the item level, to encounter these future requirements," he continues.

Using digital press technology to customize product packaging within manufacturing chains adds a degree of agility that allows pharmaceutical manufacturers to react more easily to legislative changes or variations in production labeling requirements, every bit it reduces reliance on external packaging providers.

The new K6 00G includes a range of solutions that accept been developed for different installation types, including off-line, near-line, top-of-line, sealed-blister-coding for printing straight on formed blister packs, and an integrated-line version adult to meet the needs of OEMs.

" Digital printing and flexible supply bondage are kickoff to play a much greater role in pharmaceutical manufacturing – and and so the K6 00G is a necessary investment to keep upwardly with time to come legislation and market trends," says Volker Watzke, EU Medical Devices sector manager at Domino.

" As Domino customers, pharmaceutical manufacturers utilizing the K6 00G solution besides accept the benefit of our global experts, who are always ready to support them when they need us," he adds. "We want to ensure that our customers are e'er in control of their lines."

When it comes to printing performance, the K6 00G achieves high-quality, reliable printing across a range of substrates – the press module has a native resolution of 600dpi and fantabulous greyscale capability. Based on Domino's market place-leading piezo drop-on-demand inkjet technology, the printer is also capable of building up imagery using multiple different driblet sizes – this improves image quality and gives manufacturers more control over their ink consumption.

" In pharmaceutical manufacturing, code quality and legibility are of primal importance, and, owing to the cost of unplanned downtime, information technology is besides imperative that machines are kept functioning at optimal operation," says Bart Vansteenkiste, Global sector managing director – Life Sciences at Domino.

" The K6 00G was adult with this level of reliability and immovability in heed with automated maintenance systems to reduce operator intervention and to go along the system running at optimal performance."

In society to achieve the highest levels of efficiency, the system can besides be supplied with unique AI software that collects, analyses, and learns from factory data to provide intelligent manufacturing solutions.

" With the K6 00G, we have combined the primal principles of Industry 4.0 to provide a solution that addresses the evolving life science environs and production challenges facing pharmaceutical manufacturers," says John McKeon, chief executive officer of Gallarus. "The new solution delivers exponential benefits in the form of ROI, cost-saving, quality enhancement, and OEE efficiencies."

The K6 00G is capable of printing at speeds of up to 75 meters per minute, and print widths range from a single print module, covering 108 millimeters (4.25 inches), upward to seven dual print modules with a combined width of 782 millimeters (thirty.viii inches). The smart i-Tech StitchLink micro-motor controller applied science enables accurate print head alignment and image stitching to attain seamless printing across a full spider web print width.

With its i-Tech CleanCap , the K6 00G cleans the impress heads when non in operation, leaving them wiped and capped, ready for the next use. This removes the need for daily print caput cleaning, protects the print heads from blockage and damage, and reduces the demand for maintenance. I-Tech ActiFlow ensures the ink is ever moving around the impress caput. This degasses the ink, preventing the formation of air bubbles that tin impact nozzle performance and increase the risk of product rejects.

" When we set up out to develop the K6 00G, nosotros wanted to develop a future-proof solution that would come across the electric current needs of pharmaceutical manufacturers and allow them to accommodate more hands to changing market trends and legislative requirements," says Watzke. "The result is a potent and reliable solution that helps to ensure compliance and patient safety while allowing manufacturers to remain active. When it comes to pharmaceutical manufacturing, the K6 00G is the solution of choice, now and in the future," he concludes.

For more information on the K6 00G, please visit https://bit.ly/2HwRcBE

mclaughlinsplaccut.blogspot.com

Source: https://packagingsouthasia.com/type-of-article/new-product/domino-launches-variable-data/

0 Response to "Domino launches variable data printing solution for pharmaceutical applications"

Postar um comentário